Company

History

Diplom-Ingenieur Harald Feuerherm laid the cornerstone for our company’s success in 1977 with a pioneering invention in the area of radial wall thickness distribution. Since then three generations have worked on the systematic further development and optimization of the PWDS®/SFDR® system: The use of this technology, which allows the optimization of the wall thicknesses of hollow plastic bodies, allows manufacturers to achieve significant savings in materials costs, cycle times, production costs, and CO2 emissions.

The further development of the technology and the family-managed company’s international expansion led to rapid growth: The cellar rooms of the residence in which company founder Harald Feuerherm developed his idea were soon no longer sufficient. After multiple relocations, we moved into our new headquarter with a large factory floor in Troisdorf in 2014. Here, three generations and fifteen employees work with innovative solutions for the extrusion blow moulding industry.

Today

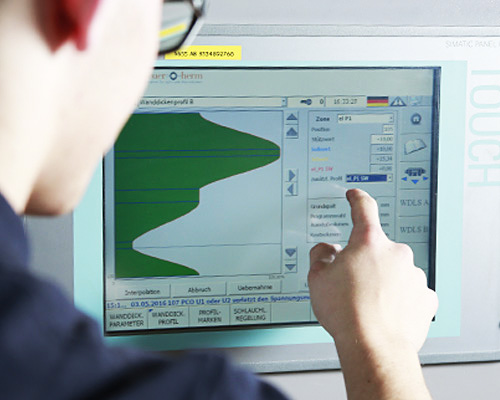

Today, PWDS®, SFDR®, and WDLS are synonyms for optimized, sustainable blow moulding manufacturing processes.

These systems make Feuerherm the leader on the world market.

Our technology is the most often sold radial wall thickness system for hollow blow-moulded bodies – more than 2,000 of them are in use all over the world. Today, a combination of PWDS® and SFDR® is used in almost all areas of plastic blow moulding. Manufacturers of hollow packaging bodies such as canisters, barrels, and IBCs, of technical parts such as plastic fuel tanks and filling tubes, and of blow-moulded leisure accessories and toys have counted on our technology for years.

PWDS®/SFDR® systems allow efficient production savings on material and energy consumption, and an increase in product quality and reliability. We deliver an all-around package to our customers: We provide consulting for the selection of the right product, adapt the system to the individual requirements, ensure smooth commissioning, and continuously optimize and maintain the systems.